Introduction: The Supply Chain Planning – Truck Load Optimization Disconnect

In the last decade there’s been a lot of talk from supply chain gurus about making supply chain management seamless from end to end. However, it’s easier said than done. In most companies, many supply chain processes remain siloed. One such example is the disconnect between supply chain planning and truck load optimization. Supply planners routinely plan purchasing, manufacturing, and outbound shipments based on detailed parameters relating to inventory levels, purchasing lead times, and manufacturing capacity. Yet in most companies, such plans seldom take into account transportation capacity or availability. Companies may have very capable transportation management systems (TMS), but these are used for execution, after purchase orders have already been placed and shipments planned, rather than during the planning stage, when key decisions are made. So while TMS truck load optimization projects may exhibit impressive results, they are only addressing half the battle. The result is a lost opportunity to increase utilization and reduce costs, increase on-time deliveries, and streamline warehouse shipping and receiving operations.

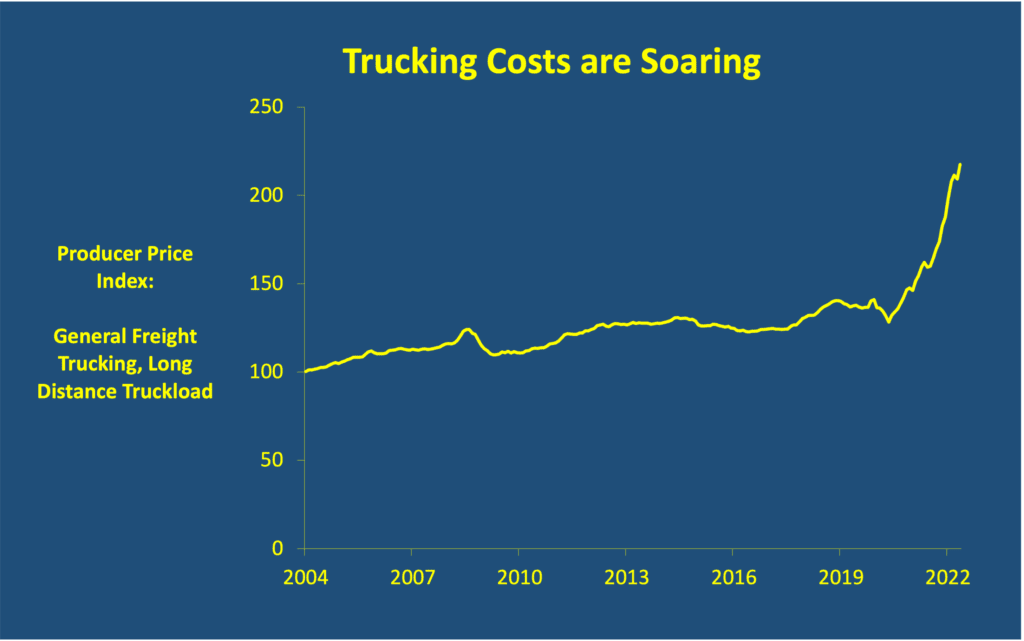

This problem has always existed, but with soaring transportation costs the last few years, there’s a new urgency to bridge the gap between supply chain planning and truck load optimization. Companies are now tackling this challenge to make the most out of precious transportation capacity.

Rising Transportation Costs

Transportation costs have been increasing steadily for years. This has been particularly bad in the U.S. trucking industry because of driver shortages and stricter hours-of-service regulations. The pandemic, followed by surging fuel costs and high inflation, has taken trucking costs to a new level, as indicated by the chart below, showing data through May 2022. Costs have increased about 60% since before the pandemic. This has increased pressure on shippers and their customers to use transportation capacity more efficiently.

Low Transportation Capacity Utilization

A number of factors result in inefficient use of our current transportation capacity. As noted above, there has been much attention paid in recent years to the shortage of truck drivers. Compounding the shortage is the fact that long haul drivers spend only 6.5 hours a day driving. This is over 40% less than the 11 hours allowed by safety regulations, according to Congressional testimony from David Correll of MIT’s Center for Transportation and Logistics. There’s also the problem of empty miles (trucks driving with no cargo after completing a delivery), with an estimated 35% of truck miles being empty in the U.S.

Less well known is the problem of low truck capacity utilization. Among trucks carrying a load, the capacity utilization is only about 57%, according to a report from the American Council for an Energy-Efficient Economy. Low transportation capacity utilization results in higher costs per unit shipped. Utilization will always be below 100%, because of urgent orders and routing considerations, but nearly all industry experts believe there is a significant opportunity to increase utilization using technologies such as truck load optimization. And solving this challenge is likely easier than solving the previously noted problems of driver shortages, low driver utilization, and empty miles.

Ironically, even though there is a lot of excess space on trucks, it’s usually not at the right place at the right time, particularly in the current environment of labor shortages. So, while many trucks are running well below 100% full, cargo is often stuck in warehouses because transportation capacity isn’t available where and when it is needed. Accordingly, observers estimate that about 30% of product shortages are the result of inadequate transportation capacity. Freight is literally being left on the loading dock because there’s no room on the truck.

Current Approaches to Truck Load Optimization

As stated earlier, many companies are using very capable TMS systems or point solutions for truck load optimization. But since these are execution systems, they are not optimizing planned purchases and shipments, but simply optimizing execution after procurement and shipment quantities and schedules have already been determined.

You may be wondering why so few people incorporate transportation capacity into their supply chain planning processes, when they incorporate things like manufacturing capacity in great detail. I believe the root cause is the historical disconnect between the transportation function and the rest of the supply chain operations within companies. Another reason could be that planners don’t want to do anything that would increase inventory and carrying costs. This is a valid concern in certain cases but as transportation cost rise, the cost savings of shipping full truckloads will often more than offset higher carrying costs. The disconnect between planning and transportation management is no longer acceptable.

The Most Pressing Need: Incorporating Truck Load Optimization into Procurement Planning

What’s usually missing today is a way for planners to take into account transportation capacity and schedule constraints before they plan purchases or shipments. Consider a company placing large orders with its suppliers, either truckload orders from a single vendor, or from a few vendors that share a third-party logistics (3PL) facility. This could be a manufacturer buying raw materials or components, or a retailer or distributor buying finished goods for resale. Ideally, the company would optimize order quantities by taking into account weight, cube, pallet, and case capacity constraints (the latter in the case of floor-loaded freight). This way, they could plan in increments of truckloads, filling trucks as close to 100% as possible. If transportation capacity is highly constrained, they should prioritize purchases so that the initial deliveries are for items at risk of stocking out. If there are multiple products being ordered, they may want to plan to have all their needs for one item shipped together in the same truck for more efficient receiving. None of this is possible unless transportation constraints are considered during procurement planning. And a TMS execution system can’t help, because such constraints need to be part of the planning process, when buyers are deciding on purchase order quantities and schedules.

In our work with customers, this procurement planning use case has been the most pressing need. The need arises when customers are paying the shipping costs and want to lower costs. It also applies when vendors are paying and impose order constraints such as “full truckload quantities only.” Another use case is for shippers planning deliveries to their customers.

A comprehensive 2019 research study from The International Council on Clean Transportation reported that Home Depot has adopted the above procurement planning approach for ocean transportation used to import products from China. The report states, “Through container optimization software, THD [The Home Depot] predetermines the type and number of stock units to be loaded onto containers before a purchase order is generated and sent to supplier factories. This allows the company to fit as much as 10% more products in each container.” As a result, they have increased container transportation utilization from 75% to 87%. This demonstrates the potential opportunity for this new approach to integrating planning with truck load optimization.

“Through container optimization software, THD [The Home Depot] predetermines the type and number of stock units to be loaded onto containers before a purchase order is generated and sent to supplier factories. This allows the company to fit as much as 10% more products in each container.”

A Critical Assessment of a Multimodal, Multinational Freight Supply Chain of a Fortune 50 Retailer

Conclusion: Benefits of This Approach

By bridging the gap between truck load optimization and supply chain planning, companies can increase truck utilization by up to 10%, in line with Home Depot’s experience with ocean shipping. Users also benefit from reduced materials shortages and lower receiving costs. And if these operational efficiencies are not enough, everyone benefits from the lower carbon footprint you get from driving fewer truck miles.