Introduction

After receiving numerous comments on my recent blog about sales and operations planning (S&OP), I’ve been inspired to delve deeper into the subject. I’ve decided to create a series of follow-up blogs regarding the intricacies of executing an S&OP process and utilizing related software. Amid a climate of economic uncertainty, businesses increasingly rely on S&OP as a crucial tool for managing volatility and maintaining operational stability. This article provides a foundation for understanding the sales and operations planning process and how software enables the process.

Definition of Sales and Operations Planning

Let’s begin by defining sales and operations planning to ensure everyone is on the same page. S&OP is a business process in which a cross-functional management team periodically monitors and revises projected demand, supply, product, and financial plans to ensure alignment and achievement of a company’s goals in key performance areas such as revenues, costs, profits, and customer service levels. S&OP plans are typically reviewed monthly and have about a 24-month rolling planning horizon.

The term integrated business planning (IBP) is often used to indicate a more strategic version of S&OP, involving a longer-term planning horizon and closer involvement by the finance department. There is an ongoing debate about whether IBP is fundamentally different from S&OP or just a term for a mature stage of S&OP. For the purposes of this article, the two terms are interchangeable. (For simplicity, we use the more common term for our product, New Horizon Sales and Operations Planning, which can facilitate different levels of S&OP process maturity, including IBP.)

How Does Sales and Operations Planning Differ from Operational Planning and Strategic Planning?

Many S&OP meetings become entangled in resolving short-term operational planning challenges. These undoubtedly need attention and may leverage the same data and software systems utilized for the S&OP process. However, S&OP should be carved out as a distinct process focused on longer-term issues. This separation ensures that the “tyranny of the urgent” does not hinder addressing crucial long-term issues.

Similarly, certain long-term strategic issues are best addressed outside of S&OP, within a dedicated strategic planning process. While S&OP routinely handles tasks such as coordinating with a new component supplier or establishing a new production line to meet increasing demand, the S&OP meeting is generally not the suitable platform for discussing substantial multi-year investments in a new manufacturing technology platform.

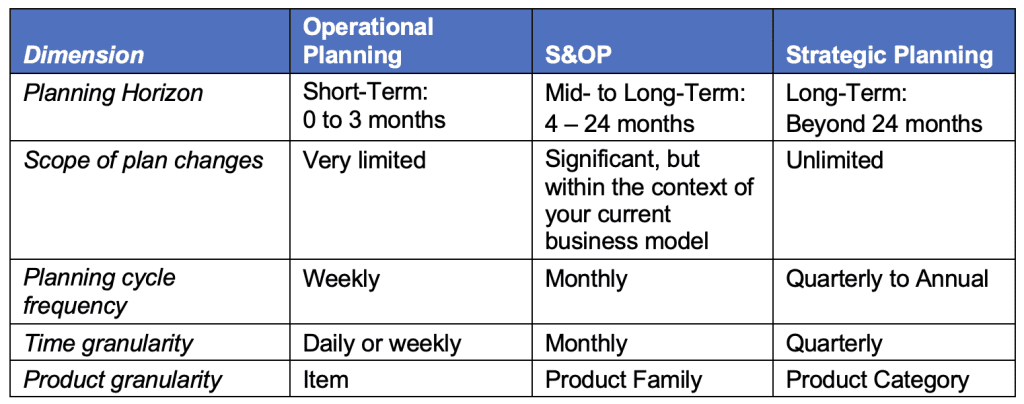

In addition to having different planning horizons from operational and strategic plans, S&OP plans are typically updated at different frequencies, encompass a different scope, and are created at different levels of time and product granularity. This stems from the principle that the longer the time horizon, the less significance granular details hold. The following table outlines these differences among the three levels of planning:

Typical Characteristics of Operational, S&OP, and Strategic Planning

The three columns above display typical values, but these will vary by industry and company. For instance, if you’re in the bourbon business, where your product may be aged up to 12 years, your S&OP process should extend that far. Another example relates to the planning cycle frequency. While one month is the traditional S&OP frequency, certain industries, such as high-tech, with its chronic long lead times and supply shortages, often update S&OP plans weekly. The chart’s purpose is not to prescribe the exact values for each cell but to emphasize that S&OP is a distinct type of planning from short-term operational planning and long-term strategic planning. Therefore, it should be conducted separately from the other two. (For this reason, New Horizon offers applications for operational demand and supply planning, a separate S&OP product, and a separate strategic planning solution.)

The Essence of Sales and Operations Planning: A Process for Identifying and Closing Performance Gaps

There is an extensive number of articles, blogs, books, and videos explaining the S&OP process in great detail. Unfortunately, sometimes the essence of S&OP can get lost in all the details. Fundamentally, S&OP is a process for identifying projected performance gaps and eliminating these gaps. The S&OP process traditionally consists of a series of review meetings to go over product, demand, supply, and financial plans before a final monthly executive review meeting. (Details and terminology differ from company to company.) In typical product, demand, supply, and financial review meetings, the respective teams identify and resolve gaps along the lines of the following:

- Product Review:

- Are our latest plans for launching new products and phasing out old products on track?

- If not, will it impact our ability to achieve our goals for revenues, costs, and profits?

- If so, what actions can we take to bridge the gap, such as getting a product launch back on schedule by substituting for a delayed component or adjusting features?

- Demand Review:

- Will our current demand forecast enable us to attain our goals for revenues, costs, and profits?

- If not, what steps we can take to boost demand or adjust the product mix, like launching a new promotional campaign or reducing the price?

- Supply Review:

- Will our current supply plan allow us to profitably meet the revised demand schedule and achieve customer service level targets?

- If not, what measures can we take to increase supply, like adding a production shift or paying a price premium to compress a component lead-time?

- Financial Review

- Do the revised product, demand, and supply plans enable the company to meet its financial targets?

- If not, how can we adjust these plans to align with our financial targets to the greatest extent possible? (Note: The financial review process occurs simultaneously with the preceding processes.)

The financial review process (sometimes referred to as integrated reconciliation) ends with a meeting (sometimes called the pre-S&OP meeting) in preparation for the executive review meeting. During this latter meeting, the management team reviews and approves recommended changes, chooses among proposed alternatives, and allocates resources as needed to meet the revised plans.

While there are many more details to the S&OP process, the essence remains the same: identifying gaps between projected and target performance, and closing these gaps as much as possible. The outcome is alignment across marketing, sales, product, supply chain, and finance organizations, forming a unified plan to achieve company goals.

The Role of Sales and Operations Planning Software

While the best S&OP software can’t compensate for a deficient process, good S&OP software is critical for running an effective S&OP process. Several characteristics are key:

Your S&OP Software Should Not Be a Spreadsheet

Spreadsheets are still quite common for S&OP, but they lack advanced capabilities such as the ability to simulate sophisticated what-if supply scenarios, preserve audit trails of plan changes, archive plans, and support post-mortem analysis. Moreover, if you’re utilizing a spreadsheet for S&OP but conducting your operational planning using traditional supply chain planning or ERP software, it becomes a persistent challenge to import plan data from your operational systems to the spreadsheet and then send your revised S&OP plans back into your operational systems for execution.

S&OP Software Should be Part of an Integrated Suite of Supply Chain Planning Applications

Many standalone S&OP, business intelligence, and financial planning applications (often under the name IBP) are still in use for S&OP. Although these may surpass spreadsheets in various aspects, they still encounter the limitations mentioned above. The substantial work in S&OP often revolves around running advanced alternative supply scenarios, a task that requires up-to-date and granular supply chain data and sophisticated supply modeling capabilities — features typically found only in integrated supply chain planning suites.

S&OP Software Should Be Able to Look Backward and Forward

A frequent challenge in S&OP meetings is getting caught up in discussing why the company didn’t meet its numbers in the past, instead of focusing on the future. S&OP should primarily revolve around ensuring the achievement of goals going forward. Therefore, your S&OP software and process should be supported by strong forecasting and demand planning capabilities, ensuring that your plans are grounded in the most accurate projection of demand possible.

Nevertheless, it’s crucial in every S&OP meeting to inquire about changes in the last month, assess if we are still on target, and if not, understand why. This is not to assign blame but to identify the source of any shortfall and implement corrective action to prevent recurrences. This entails conducting a post-mortem analysis, examining the audit trail of past plan changes, modifying past assumptions, updating plans, and documenting the reasons for plan changes. Effective S&OP software is essential for efficiently and comprehensively carrying out these tasks.

Conclusion

This high-level overview of S&OP only scratches the surface of a huge topic, but I believe it provides crucial context for company teams embarking on S&OP initiatives. S&OP can play a key role in enabling companies to meet their business goals, particularly in a volatile business climate. However, to succeed, there must be a clear understanding of the purpose of S&OP, ensuring practitioners don’t get bogged down in methodology without seeing the forest for the trees. Stay tuned for upcoming articles that will explore the topic in more detail.

To Learn More

To learn how New Horizon can help with your S&OP process, please contact us – we’d love to talk.